Do you have an asphalt maintenance plan in place for your facility? As asphalt surfaces age, erode and become brittle, proper periodic assessment and treatments are essential in maintaining a quality surface and infrastructure. The appropriate course of action can save time and money by making sure the maintenance applications are matched to the severity of the pavement problems.

Understanding Defects

There are typically three types of asphalt failures: Surface, Bond, and Structural Failures. For surface failures there can be raveling, and transverse or longitudinal cracking problems. Raveling is the loss of aggregate from the surface as a result of abrading action from wheels. Longitudinal cracks run in the direction of traffic and transverse cracks are 90 degrees to longitudinal cracks. Longitudinal cracks are typically caused from shrinkage.

Bonding failures are usually in the form of slippage between two layers of surfacing causing cracks in the upper layer. In some cases the combination of bonding and crack failures causes the top layer to flake off in chunks.

The most severe defects are structural cracking which can include fatigue cracking and rutting. Fatigue cracking results from the surface being flexed up and down from heavy loads going by. The cracks are very close together and look like an alligator's skin. This defect occurs when the underlying road section can no longer support the loads being applied to the pavement. One heavy truck can flex and damage a road more than thousands of cars passing over the same spot. Rutting is a depression of the pavement in the wheel path and is usually continuous throughout a pavement. It can occur in just the asphalt layer or throughout the entire infrastructure of asphalt, base, and soil.

Types of Treatments

The difference types of actions one can choose will vary with the defects and extent of damage found on the pavement surface. The potential solutions can include surface seal coats, crack filling, slurry seals, selective dig-outs and patching, or full overlays.

Within the use of surface seal coats, there are several to choose from. They include slurry, cape, micro-surfacing, fog, and rubberized chip seals to name a few. A fog seal contains no aggregate or sand and is spray applied to keep the surface aggregate in place. A surface seal coat is a mixture of sand and asphalt emulsion with other fillers. It provides a uniform black surface and protects from UV damage and reduces water intrusion. A slurry seal consists of emulsified asphalt binder, a graded fine aggregate additive and water and is applied by machines with pressure.

An overlay is used over the top of an existing pavement surface to strengthen and protect the original structure. It can be applied at various thicknesses and also can be rubberized. Sometimes milling is required before the overlay when excessive heights are an issue to prevent any potential trip hazards. Also the use of paving grids and fabrics over the top of an existing cracked pavement can provide additional strength and water intrusion protection.

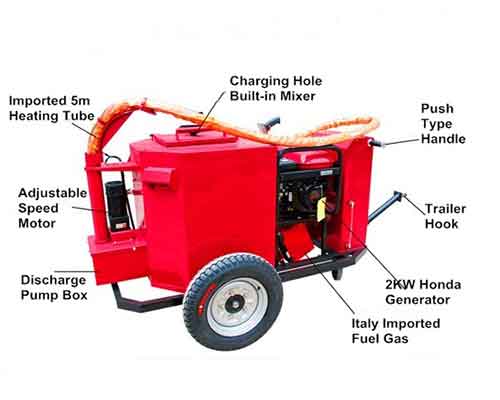

Asphalt crack filler machine is a kind of asphalt crack repair machine which is suitable for filling the cracks of road, expressway, asphalt and concrete pavement of municipal, airports, squares, industrial parks,as well as filling cracks of complicated and irregular pavement. As an indispensable road maintenance machine, it is mainly used for preventive maintenance of road surface diseases and in conjunction with road grooving machine and air blower. We use the most advanced irrigation sewing technology and produce and produced a variety of models of asphalt crack filler machine for sale, which will be the good choice for customers. Feel free to send us email to contact us more about your requirements, we will reply you in 24 hours.

没有评论:

发表评论