The Composition of Shot Blasting Machine:

The automatic shot blasting machine consists of a mobile trolley ( remote control ), a machine, a shot blasting chamber, a storage chamber, a sand separator, a two-stage dust collector system, a dust, a pneumatic device, and an electric control device.

Road Application of Road Shot Blasting Machine:

The collecting and separating device of the road shot blasting equipment has a simple structure and a good separation effect, thereby ensuring good throwing quality. Increased the life of consumables. The road shot blasting machine expands the application of the shot blasting process from the surface treatment of the parts to various fields such as road maintenance and hull derusting. The structure of the floor shot blaster, reasonable selection of various parameters, the laboratory preliminary verification, the equipment can smoothly recover the projectile for circulation, the separation effect between the projectile and the magazine is better, the part that is thrown is uniform, and the throwing effect is good. The machine can meet the actual needs and is suitable for the cleaning of the machinery industry and roads and airport pavements.

Precautions:

- Pay attention to waterproofing. Because the machine adopts the principle of machinery, and the power of this principle is not only some electronic equipment, but the most important one is the motor. Therefore, it is necessary to pay attention to waterproofing when it rains.

- Pay attention to lubrication. In order to make the equipment more smooth, it is recommend to apply lubricating oil to the mechanical connection of the equipment and the motor at intervals.

- Pay attention to maintenance. Any product needs maintenance. Just like a car, it needs regular inspection and maintenance. The road shot blasting machine is no exception. Regular maintenance of the road shot blasting machine can make the life of the equipment extend.

- Pay attention to the appropriate. Because the amount of work on the road is generally large, so many companies are working 24 hours a day, which leads to the machine to keep running, it is recommend to stop the equipment properly when the work is over.

Advantage of Floor Shot Blaster:

- Operation and preparation are simple, clean up at any time, and evacuate at any time.

- Adopt frequency control to ensure accurate realization of various functions.

- According to the different conditions of the road surface, the cleaning speed, the supply amount of the steel pill, the pulse backflushing time period, the cleaning interval of the dust filter cartridge, etc. can be set, and the adjustment of the parameters can be adjusted to achieve the desired cleaning effect.

- The working width is wide and the efficiency is high.

- The whole construction process is dust-free and pollution-free, which is conducive to environmental protection and the health of construction workers.

- The pavement structure is basically not damaged during construction.

- The pulse automatically blows back the dust, which can achieve continuous operation.

- Steel shots are automatically circulated inside the equipment and the consumption is very low.

- The structure of the whole machine is reasonable, the disassembly is quick, and it is convenient to repair and replace the wearing parts.

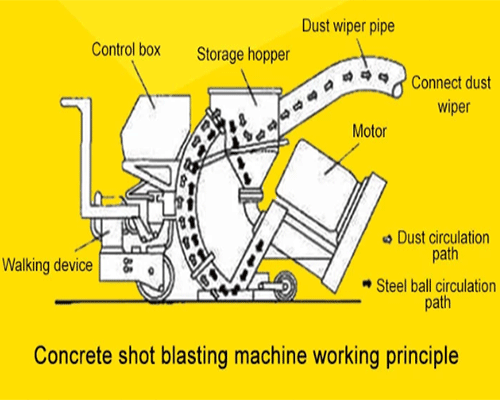

How Shot Blasting Machine Works:

Working Conditions:

- Working surface unevenness <20mm; No water and relatively dry; Slope <25º.

- Ambient temperature: -20℃~60℃. Steel plate surface temperature is greater than 3℃.

- Humidity:

- The relative humidity of the steel surface when shot blasting is not more than 90%.

- The relative humidity of concrete shot blasting is not more than 95%.

Concrete Shot Blasting Machine Operating Instruction:

Start-up Steps:

- Turn on the vacuum cleaner.

- Prepare to operate the machine, confirm that the valve handle is in the “off”position, and press the button “ Control ON”. Insert the walking pin and press “ Blast Wheel ON”. At this time, the shot blasting starts. Observe the ammeter. When the shot blasting motor starts, it needs a large current until the motor reaches a certain speed. When the motor reaches the rated speed. At the speed, the current will drop to the no-load current state.

- Set the walking direction to “Backward”. The device walks, and then set the walking speed of the device at the walking speed adjustment knob.

- When shot blasting on the concrete surface, the valve is only opened when the machine is walking, otherwise the pit will be thrown on the concrete surface in a short time.

Shutdown Steps:

- Close the valve handle completely;

- Release the walking kneading handle and stop the walking motor;

- Press the red “Control Off”.

- After a few minutes, press “Fan Off” and “Compressor Off”.

没有评论:

发表评论